Products

Suitable for application in auto parts, consumable electronics and household appliances. These can require perfect forming. By combining progressive die with pendulum curve, the productivity can possibly be doubled, which saves more than 50% of energy. Furthermore, automated transfer production line can also be added to upgrade the productivity.

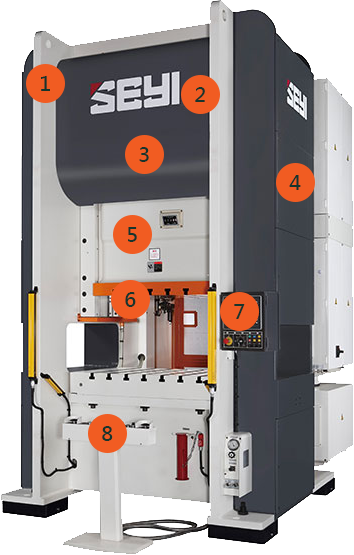

1

Intersected parallel framework, 8-point Guided Slide

The highly rigid intersected parallel framework emphasizes on longitudinal and transverse rigidity The 8-point guided slide emphasize on support with guide rails that increases stability of punch and effectively resists eccentric loading.

2

Exclusive servo motor for press machine

Low speed High torque

Features a extreme acceleration/ deceleration

Extremely precise dimensions

High efficiency

(Other brand)

Due to insufficient torque at low revolution, high revolution has to be used with deceleration as well.

3

Centralized circulation of oil lubrication

Centralized circulation of oil lubrication

This is designed for various special servo design.

4

Energy conservation Space saving Improvement in production volume

The adoption of electrical utilizer prevents high power output at the instant of pressing (power consumption same as conventional press machine). Replacement of hydraulic machine, improvement in production volume and reduction in power consumption The pendulum movement saves energy by 50% (time of non-processing stroke saved) The noise reduces by 30 times and die lifetime extends by more than 50%.

5

8 default modes

Time of non-processing stroke saved for higher productivity Limitless press movement that stops at any position up, down and speed shifting

6

Best B.D.C. Accuracy

No hydraulic pressure on electronic overload system for less factors of variables and stable precision on bottom dead center

7

User-friendly operation interface and monitoring software

With memory capacity for 200 sets of die information, the machine speeds up efficiency in die replacement and production. The setup of “absolute value in speed” allows precise control (the curvature setup method by other brand makes calculation troublesome) on monitoring production, quality and detecting abnormity.

8

Hand wheel mode for convenient die calibration

Hand wheel mode for convenient die calibration

The punch can move freely for ease of setup.

|

Model |

SD1-80 |

SD1-160 |

SD1-200 |

SD1-300 |

||

|

Tonnage Capacity |

kN |

800 |

1600 |

2000 |

3000 |

|

|

Stroke Length |

mm |

180 |

220 |

250 |

300 |

|

|

Stroke per Minute |

spm |

~ 80 |

~ 60 |

~ 50 |

~ 40 |

|

|

Tonnage Rating Point |

mm |

5 |

6 |

6 |

6 |

|

|

Die Height |

mm |

330 |

400 |

450 |

550 |

|

|

Slide Adjustment |

mm |

80 |

100 |

110 |

120 |

|

|

Slide Area(LRxFB) |

mm |

700x460 |

900x580 |

1000x670 |

1150x800 |

|

|

Bolster Area(LRxFB) |

mm |

950x680 |

1150x760 |

1300x870 |

1450x1050 |

|

|

Bolster Thickness |

mm |

140 |

165 |

180 |

200 |

|

|

Bolster Height |

mm |

900 |

940 |

1020 |

1040 |

|

|

Window Opening(FBxUD) |

mm |

680x280 |

760x350 |

870x400 |

1050x450 |

|

|

Press Height |

mm |

2962 |

3502 |

3819 |

4345 |

|

|

Upper Die Weight |

Ton |

0.3 |

0.5 |

0.8 |

1.3 |

|

|

Required Air Pressure |

MPa |

0.55 |

0.55 |

0.55 |

0.55 |

|

|

Die Cushion |

Capacity |

kN |

60 |

80 |

100 |

140 |

|

Stroke Length |

mm |

95 |

110 |

130 |

140 |

|

|

Die Cushion Area(LRxFB) |

mm |

480x340 |

560x370 |

700x450 |

700x450 |

|

|

Model |

SD2-160 |

SD2-200 |

SD2-300 |

SD2-400 |

SD2-500 |

||

|

Tonnage Capacity |

kN |

1600 |

2000 |

3000 |

4000 |

5000 |

|

|

Stroke Length |

mm |

220 |

250 |

300 |

350 |

350 |

|

|

Stroke per Minute |

spm |

~ 60 |

~ 50 |

~ 40 |

~ 40 |

~ 40 |

|

|

Tonnage Rating Point |

mm |

6 |

6 |

6 |

6 |

6 |

|

|

Die Height |

mm |

450 |

500 |

600 |

650 |

650 |

|

|

Slide Adjustment |

mm |

100 |

110 |

120 |

130 |

130 |

|

|

Slide Area(LRxFB) |

mm |

1620x580 |

1900x670 |

2280x800 |

2380x1000 |

2380x1100 |

|

|

Bolster Area(LRxFB) |

mm |

1910x760 |

2200x870 |

2580x1050 |

2680x1200 |

2680x1300 |

|

|

Bolster Thickness |

mm |

160 |

170 |

200 |

200 |

200 |

|

|

Bolster Height |

mm |

950 |

1000 |

1150 |

1250 |

1250 |

|

|

Window Opening(FBxUD) |

mm |

760x400 |

870x450 |

1050x500 |

1200x550 |

1300x550 |

|

|

Press Height |

mm |

3573 |

3954 |

4589 |

4939 |

5300 |

|

|

Upper Die Weight |

Ton |

0.8 |

1.3 |

1.8 |

2.5 |

2.7 |

|

|

Required Air Pressure |

MPa |

0.55 |

0.55 |

0.55 |

0.55 |

0.55 |

|

|

Die Cushion |

Capacity |

kN |

80x2 |

100x2 |

140x2 |

140x2 |

140x2 |

|

Stroke Length |

mm |

110 |

130 |

140 |

140 |

140 |

|

|

Die Cushion Area(LRxFB) |

mm |

560x370x2 |

700x450x2 |

700x450x2 |

700x450x2 |

700x450x2 |

|

※ This specification is subject to change without notice.